b.sure® – Monitoring of your process data

In pharmaceutical production, not all process systems are supervised by the same person. This means that not all processes are consistently monitored on a permanent basis. In order to detect deviations from the process parameters or error messages at an early stage, the system operators must have access to the operating panels.

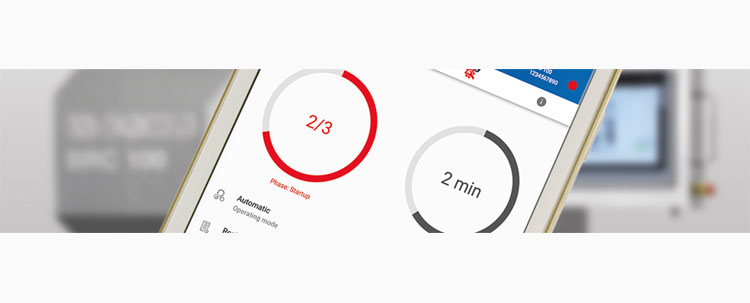

b.sure®: Keep track of your process at all times

The PLC communicates operating data and parts of the process data via a communication server to the mobile terminals and PC workstations. The system operator is not only informed in the event of a fault, but also when the parameters are outside the set-points. In addition, the operator can supervise and monitor several systems in parallel and respond in the event of errors and deviations. This gives the operator a valuable time advantage to initiate cor-rective measures at the system and safeguard the quality of the product.

b.sure®: Implementation in your process

Many of the solutions available on the market today operate via cloud services and communicate data outside the company. b.sure® follows another approach and keeps the data in the company, keeping true to the motto „Your data belongs to you“. A separate communications server is installed in the operator network, which records the respective system data. Using software that prepares and provides the data for the app of the end devices, a corresponding message is sent to the end devices via an email service in the event of an error. b.sure® is web-based and can be opened either on the respective device or via the sent email. To prevent unauthorized access, an administrator must give appropriate authorization to specific operators on the communications server. Within the application the different systems can be selected and viewed, but the processes can-not be changed via b.sure®.

b.sure® informs you of:

- customer‘s system name with serial number

- operating status (process active)

- remaining process time

- batch data, batch number and recipe

- process values (e.g. force, gap width and throughput)

- errors and status messages (e.g. emergency stop or if actual values are outside the permitted specified range.)

- maintenance mode (information about upcoming maintenance and calibration) with notification function

- predefined contact form for a quick service request to L.B. Bohle

b.sure® – Your advantages at a glance:

- avoid and reduce downtime

- timely active influence in the event of process deviations

- location-independent information on the status of the systems via mobile devices (WIFI) throughout the entire company

- status display is possible both on smart devices and the desktop PC

- data remains in the customer network – no external communication

- mono-directional communication – not possible to directly influence the process via the end devices